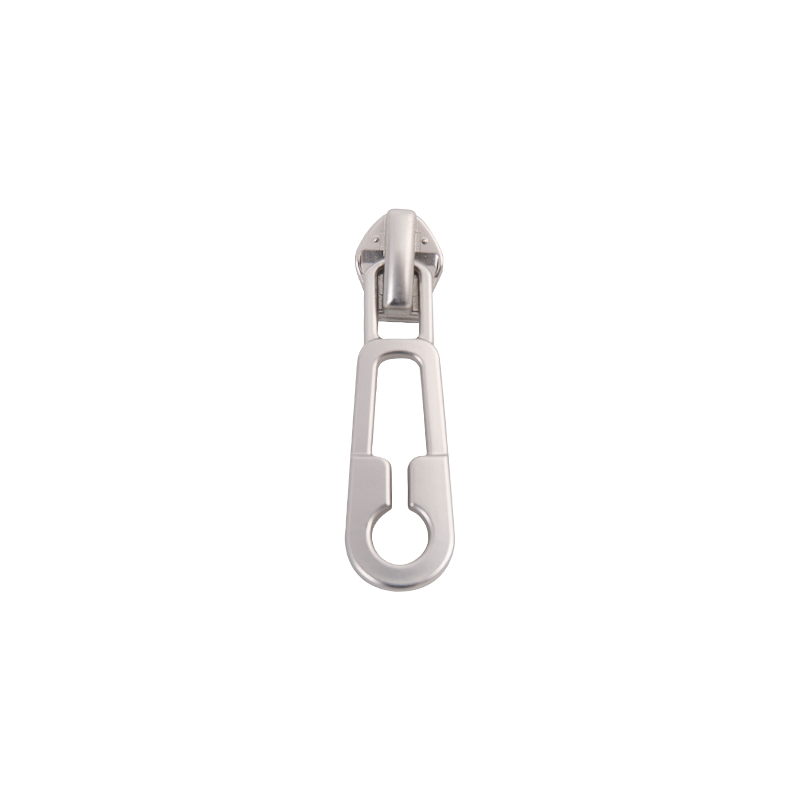

Nylon Zipper Slider is the core component of the nylon zipper system. Its quality and usage directly affect the smoothness of the zipper's opening and closing, service life, and overall functionality. Whether in clothing, luggage, or outdoor equipment, the correct use and maintenance of nylon zipper heads are essential to maintaining product performance. The following discusses how to achieve the durability and smooth operation of nylon zipper heads from three aspects: selection, use, and maintenance.

During the purchase stage, attention should be paid to quality and matching. High-quality nylon zipper heads are usually made of zinc alloy, copper, or high-strength plastic, with good wear resistance and corrosion resistance. At the same time, it is necessary to select a suitable zipper head according to the width and model of the zipper teeth to avoid jamming or slipping due to size mismatch. In addition, it is recommended to give priority to zipper heads with anti-jump tooth design or automatic locking function to improve safety and stability.

During daily use, attention should be paid to the operation method. When opening or closing the zipper, the zipper head should be pulled slowly and evenly, and sudden force or oblique pressure should be avoided to prevent the zipper teeth from deforming or the slider from breaking. If you encounter a slight jam, do not force it. You should first apply a lubricant (such as paraffin or silicone oil) to the zipper teeth for lubrication. When used in dusty or humid environments, the zipper surface and the inside of the zipper head should be cleaned regularly to prevent foreign objects from entering and causing wear. For zippers that are frequently opened and closed (such as backpacks or suitcases), it is recommended to choose a design with a two-way zipper head for more flexible operation and reduced local wear.

Regular maintenance and care are important links in extending the life of nylon zipper heads. Every once in a while, you can use a soft cloth to dip a small amount of lubricant and gently wipe the zipper teeth and zipper head slide to keep them smooth. For zipper products that are not used for a long time, you can apply a small amount of talcum powder after the zipper is closed to prevent adhesion or oxidation. If the zipper head is found to be loose or not sliding smoothly, it should be replaced in time to avoid affecting the overall structural integrity. In addition, when washing clothes or bags, try to pull up the zipper before washing to reduce the damage to the zipper structure caused by mechanical friction.

It is also necessary to pay attention to the impact of environmental factors on nylon zipper heads. High temperatures may cause plastic parts to deform, while low temperatures may make the material brittle, so it should be avoided to expose it to extreme temperatures for a long time. For products used outdoors or in special working conditions, professional-grade zipper heads with waterproof, UV-resistant or corrosion-resistant properties can be selected to enhance adaptability and durability.

The durability and smooth performance of nylon zipper heads depend not only on product quality, but also on their correct use and scientific maintenance. Through reasonable selection, standardized operation and regular maintenance, not only can the service life of the zipper system be effectively extended, but also the overall product experience can be improved. Both manufacturers and end users should pay attention to the management of this detail component to achieve dual guarantees of functionality and practicality.

en

en  русский

русский 한국어

한국어 get a free quote

get a free quote