Metal buttons have long been a staple in fashion, uniforms, and home textiles. Their durability, aesthetic versatility, and functional advantages make them a preferred choice over plastic or wood alternatives in a wide range of applications. From high-end designer garments to workwear and outerwear, metal buttons provide a unique combination of strength, longevity, and visual appeal that other materials struggle to match.

While plastic and wood buttons can serve decorative or budget-conscious purposes, they often fall short in demanding applications where repeated use, laundering, and mechanical stress are factors. Metal buttons, crafted from materials such as brass, stainless steel, or aluminum alloys, maintain their shape, resist wear, and provide a sense of premium quality that resonates with consumers and manufacturers alike.

Durability and Strength Advantages

Durability is one of the most significant reasons metal buttons are preferred. Unlike plastic, which can crack or warp under heat or impact, and wood, which can split or absorb moisture, metal buttons offer superior resistance to mechanical stress. They can endure repeated fastening, washing, and exposure to environmental factors without compromising structural integrity.

High-quality metal buttons also provide enhanced longevity in garments and accessories. Brass and stainless steel buttons resist corrosion and maintain their finish over time, making them ideal for outerwear, uniforms, and items subject to frequent use. This durability reduces replacement costs and enhances the perceived value of the clothing item.

Key Strength Benefits

- Resistant to cracking, breaking, and deformation

- Long-lasting even with frequent use and laundering

- Withstands exposure to heat, moisture, and chemicals better than wood or plastic

- Reduces garment maintenance and replacement needs

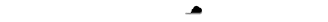

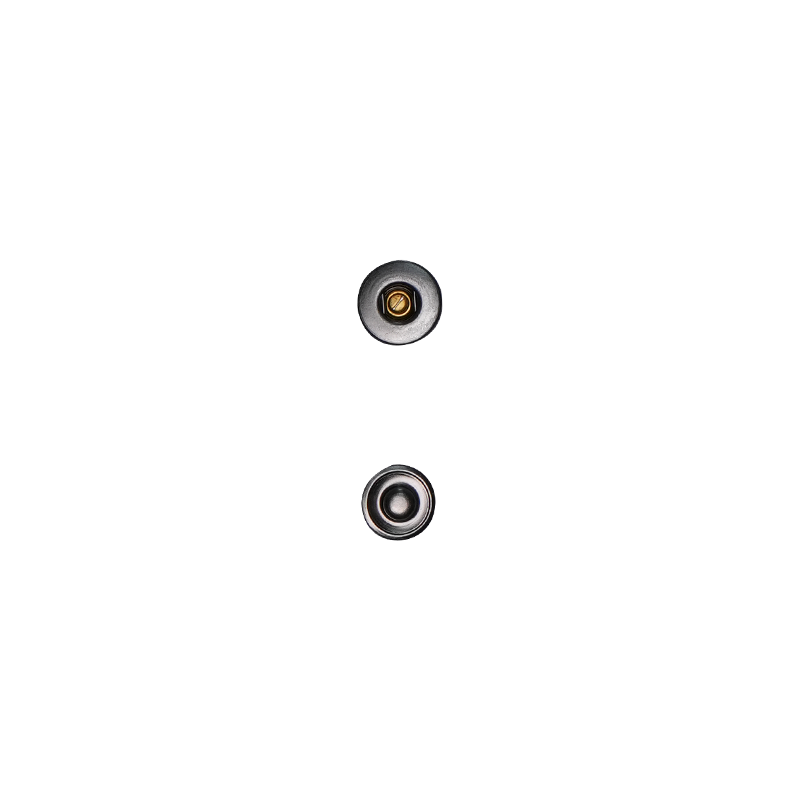

Aesthetic and Design Flexibility

Metal buttons offer unmatched aesthetic versatility. They can be polished, brushed, plated, or embossed with intricate designs, logos, or textures. This flexibility allows designers to integrate buttons as functional hardware and decorative elements, creating cohesive visual appeal in garments, bags, and accessories.

In contrast, plastic buttons are limited in color stability and finish durability, and wood buttons often require coatings to maintain appearance and resist moisture. Metal buttons maintain their shine and texture over time, offering consistent quality that enhances brand perception and consumer satisfaction.

Design and Style Advantages

- Wide range of finishes: polished, matte, antique, or plated

- Custom engraving and embossing options for branding or decorative purposes

- Ability to match or contrast with garment materials for visual impact

- Maintains consistent appearance over time compared to plastic or wood

Functional Advantages in Garment Applications

Beyond durability and aesthetics, metal buttons enhance functionality. They provide secure fastening for heavy or layered garments, such as coats, jackets, and uniforms. The weight and rigidity of metal buttons prevent accidental unfastening and support repeated mechanical stress.

Metal buttons also allow for specialized applications, such as magnetic closures or integrated rivets, which are not feasible with most plastic or wood buttons. These additional functionalities expand design possibilities and improve garment usability in professional, outdoor, and high-performance contexts.

Functional Benefits

- Secure fastening for heavy fabrics and layered garments

- Supports additional features such as rivets or magnetic closures

- Provides consistent performance in high-stress applications

- Compatible with industrial sewing and automated production processes

Sustainability and Lifecycle Considerations

Sustainability is an increasing consideration in fashion and textile manufacturing. Metal buttons offer an extended lifecycle compared to plastic and wood alternatives. They are often recyclable and maintain performance over decades, reducing environmental impact and the need for frequent replacements.

Wood buttons, while biodegradable, may require forest resources and coatings, and plastic buttons contribute to long-term pollution. Metal buttons, particularly those made from recyclable alloys, provide a balance of performance, aesthetics, and environmental responsibility, making them a preferred choice for eco-conscious brands.

Sustainability Benefits

- Long service life reduces replacement and waste

- Recyclable material supports circular economy initiatives

- Lower environmental impact over the product lifecycle

- Supports sustainable branding for fashion and uniform industries

Comparison Table: Metal vs Plastic vs Wood Buttons

| Feature | Metal Buttons | Plastic Buttons | Wood Buttons |

| Durability | High; resists wear, cracking, and impact | Moderate; may crack or fade over time | Moderate; can split or warp with moisture |

| Aesthetic Options | Wide range; finishes, engraving, plating | Limited; color fades, finishes less durable | Natural look; limited finish options |

| Functionality | Supports heavy garments, added features | Lightweight only; limited stress resistance | Moderate; may weaken under heavy use |

| Sustainability | High; recyclable, long life | Low; contributes to plastic waste | Moderate; biodegradable but limited durability |

Conclusion: Why Metal Buttons Remain a Top Choice

Metal buttons combine durability, aesthetic versatility, functional reliability, and sustainability, offering advantages that plastic and wood alternatives cannot consistently provide. From premium fashion to uniforms and outerwear, their long-term performance, customizable finishes, and recyclability make them the preferred choice for designers, manufacturers, and consumers alike. By choosing metal buttons, brands enhance product value, reduce maintenance, and support environmentally conscious practices without compromising style or function.

en

en  русский

русский 한국어

한국어 get a free quote

get a free quote